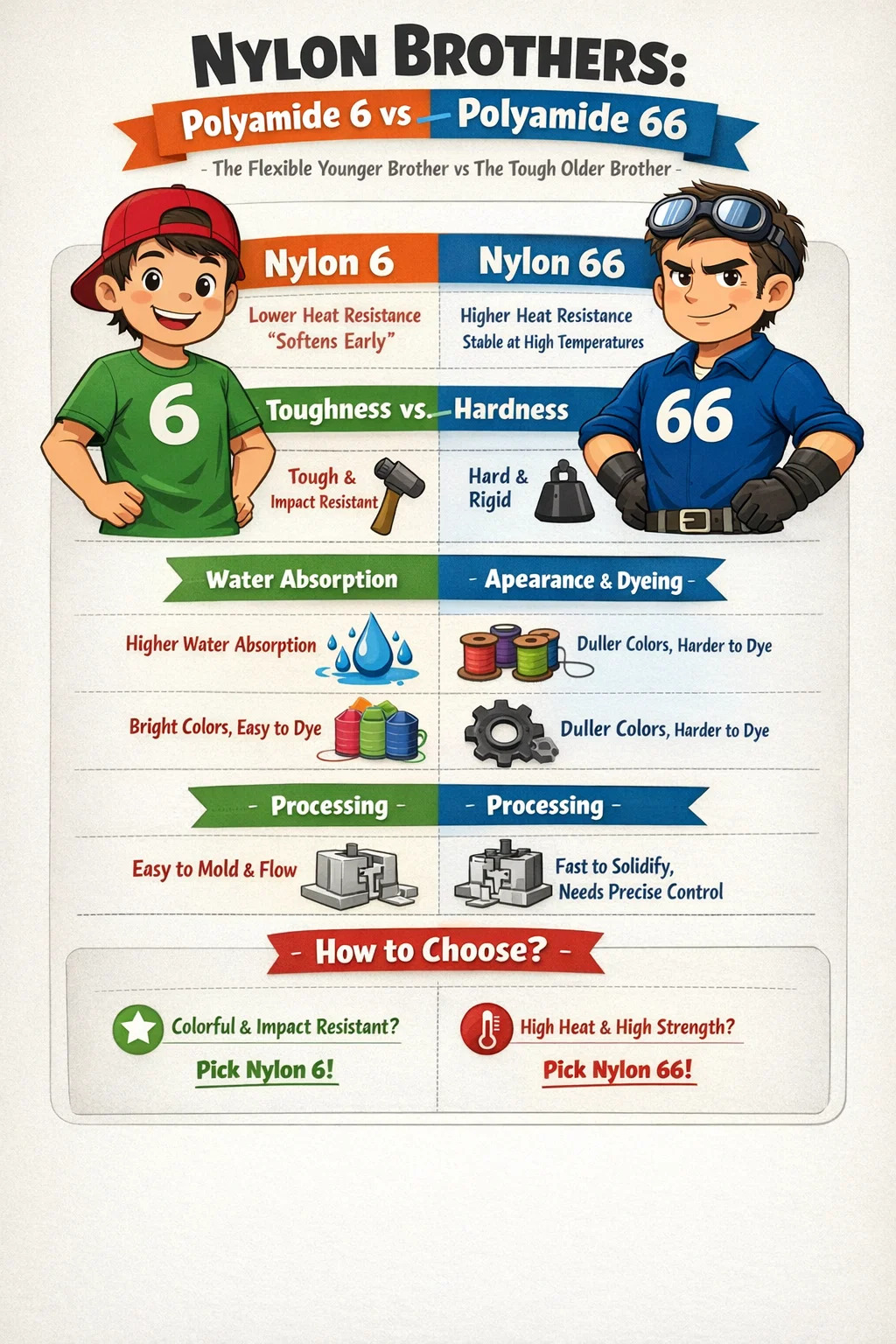

Although Polyamide 6 (Nylon 6) and Polyamide 66 (Nylon 66) sound very similar, in the world of plastics processing and everyday products, they have quite different "personalities" and "strengths."

You can think of them as brothers: the older brother 66 is more stable and heat-resistant, while the younger brother 6 is more flexible and easier to process.

▸ Resistance to Heat

This is the most obvious difference between the two.

Polyamide 66 : It has better heat resistance. If a part needs to work in a relatively hot environment for a long time (such as parts near a car engine), 66 is usually chosen. It doesn't soften easily when heated and maintains its shape.

Polyamide 6: Its heat resistance limit is slightly lower than its brother's. At very high temperatures, it will start to "soften" earlier than 66.

▸ Toughness and Hardness

Polyamide 6 (the younger brother): Its characteristic is good "toughness," meaning it's more resistant to drops and impacts. Even in cold weather, it's less likely to crack. If you need something impact-resistant, this is the right choice.

Polyamide 66 (the older brother): It's harder and more rigid. If you need a part that can bear weight or not deform, 66 will perform better. However, relatively speaking, it may not be as "tough" as its younger brother when subjected to severe impacts.

▸ Water Absorption

Nylon materials all have the characteristic of absorbing water.

Polyamide 6: Its water absorption rate is slightly higher than 66. After absorbing water, it becomes softer and its toughness increases, but its size may change slightly.

Polyamide 66: Although it also absorbs water, it's relatively more restrained, and its dimensions remain more stable in humid environments.

▸ Appearance and Dyeing

Polyamide 6: It's excellent for making fibers and beautiful parts. Because it's easier to dye, the resulting colors are very vibrant, and the surface has a better gloss, making it look brighter. Polyamide 66: The colors are usually not as vibrant, and dyeing is slightly more difficult, so it is more often found in "invisible" internal industrial parts.

▸ Processing characteristics in the factory:

Polyamide 6: When melted in factory machines, it flows relatively quickly, easily filling the mold like water. It has a lower processing temperature and is more "manageable."

Polyamide 66: It solidifies very quickly in the mold. While this can improve production efficiency, it also requires higher control over the machinery; a slight lapse in attention can lead to premature hardening before the mold is fully filled.

▸ How to choose?

If you prioritize cost-effectiveness, attractive colors, and impact resistance: choose Polyamide 6.

If you prioritize high temperature resistance, high hardness, and dimensional stability: choose Polyamide 66.